D-ring vs oval heavy duty carabiner strength.

When your safety depends on a carabiner, understanding the fundamental strength differences between a D-ring and an Oval shape is not just technical knowledge—it's critical for risk management. While both are used in climbing, rescue, and industrial work, their designs lead to significant differences in strength, safety, and ideal applications. Choosing incorrectly can compromise your entire safety system.

This article delves into the engineering and mechanics behind these two common shapes to help you make an informed decision based on your specific needs.

The Core Difference: How Force is Distributed

The primary distinction lies in how each shape manages and distributes load.

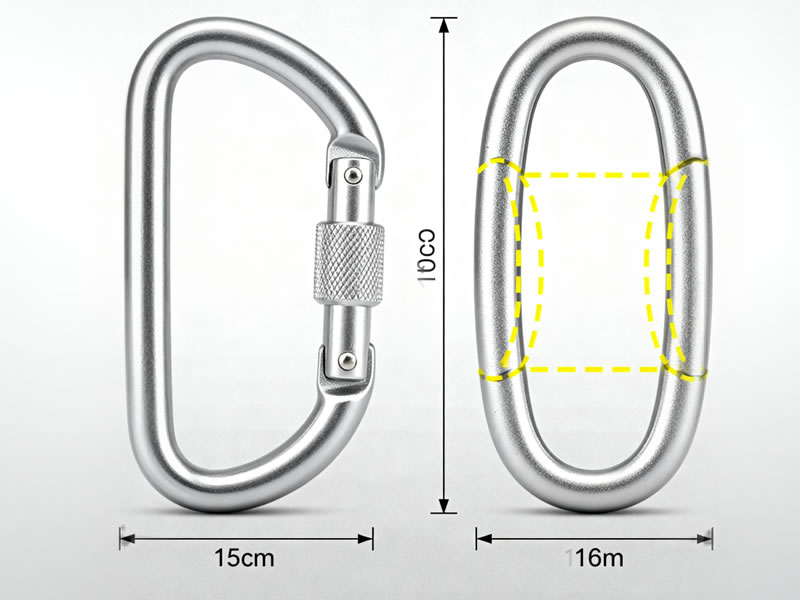

- D-ring Carabiner Strength: The D-shape is a masterpiece of efficient engineering. Its design ensures that almost the entire load is directed along the long, straight spine of the carabiner-2-9-10. This creates an optimal strength-to-weight ratio-3-4. Because the force travels in a relatively straight line from the gate to the spine, the D-ring is inherently stronger and can withstand greater impact forces, making it the preferred choice for life-saving applications-1-2.

- Oval Carabiner Strength: The symmetrical O-shape distributes the load evenly across both sides of the carabiner-2-9-10. While this creates a balanced feel, it means the strength is lower than a D-ring of comparable size and material-1-7. The metal on the curved sides must withstand the same force as the spine, which is a less efficient use of material.

The following table provides a clear, at-a-glance comparison of their key characteristics:

| Feature | D-ring Carabiner | Oval Carabiner |

|---|---|---|

| Load Distribution | Concentrated on the strong spine-2-9 | Evenly distributed across both sides-2-10 |

| Typical Strength (Major Axis) | Higher (e.g., 24-28 kN or 2000-3000 kg)-2-6-9 | Lower (e.g., 15-18 kN or 1500-1800 kg)-2-9 |

| Weight Efficiency | Excellent (higher strength for weight)-3-4 | Good, but less efficient than D-shape |

| Primary Use Cases | Lead climbing, protection points, rescue, high-load scenarios-2-9 | Aid climbing, gear organization, rappelling with multiple pieces-1-3-7 |

| Internal Space | Sufficient, but can be narrower | Larger and more versatile for multiple gear loops-1-3-7 |

🛠️ Application-Based Recommendations

Your choice should be dictated by the specific task.

- When to Choose a D-ring: For any situation involving potential high-impact loads or where safety is paramount, the D-ring is the unequivocal choice. This includes:Rock and Ice Climbing: Especially for lead climbing and critical protection points where a fall would generate high forces-9.Rope Rescue & Industrial Work: These environments demand the highest strength and reliability, which the D-shape provides-5.Connecting a Belay Device: The belay master point requires a strong, secure carabiner, almost always a locking D-shape.

- When an Oval Might Be Suitable: The oval's balanced design offers advantages in specific, lower-risk scenarios:Aid Climbing: The symmetrical shape is less likely to shift or get stuck when manipulating multiple pieces of gear-1-7.Rappelling with an Italian Hitch: The smooth, round sides allow the rope to move more freely-1-3.Organizing Gear on a Harness: The larger internal space is handy for carrying multiple slings or other equipment-7.

The Critical Importance of Locking Mechanisms

For any heavy-duty application, a locking carabiner is non-negotiable-3-4. Whether screw-gate or auto-locking, this feature prevents the gate from accidentally opening against a rock or other object, which can reduce the carabiner's strength by up to two-thirds-2-9. Both D-ring and oval carabiners are available in locking models for critical connections.

🔍 Safety Standards and Certification

Regardless of shape, always look for certification marks from recognized international bodies. These include:

- UIAA (International Climbing and Mountaineering Federation): The global benchmark for climbing equipment safety-2-10.

- ASTM F1774: The specific standard for climbing and mountaineering carabiners, which outlines rigorous strength tests-8.

These engravings on the carabiner's spine guarantee it has been tested to meet minimum strength requirements. For heavy-duty use, expect major axis strength ratings to be 22 kN (approx. 4,950 lbf) or higher-6.

Conclusion

The debate between D-ring and oval heavy duty carabiners is settled by physics: the D-ring is structurally superior for strength. Its efficient load distribution makes it the safest choice for absorbing the high-impact forces of a fall. Reserve oval carabiners for specialized, low-load situations where their symmetrical space is beneficial.

Before your next adventure, always inspect your gear for cracks, grooves, or gate malfunctions-1-9. When in doubt, choose a certified, locking D-ring carabiner—your safety is worth the investment.