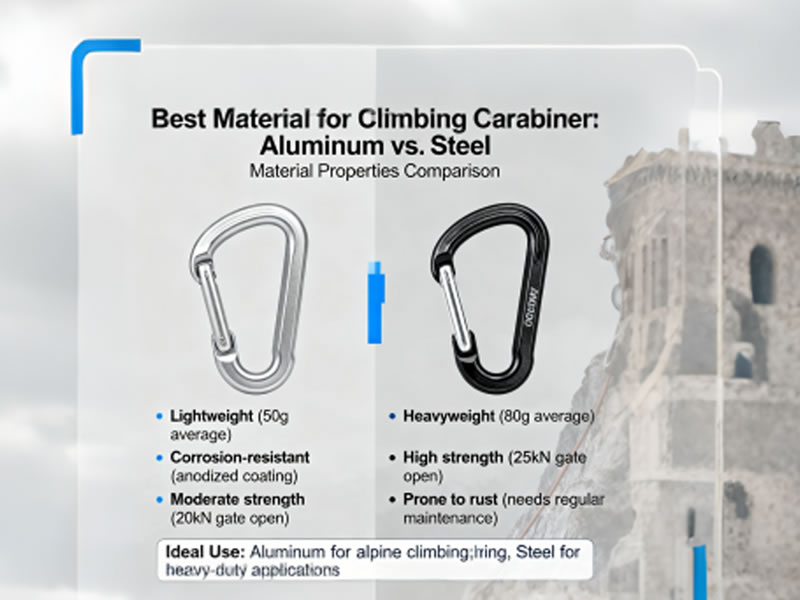

Best Material for Climbing Carabiner: Aluminum vs. Steel

The choice between an aluminum and a steel carabiner is one of the most fundamental decisions in a climber's gear selection. It's a classic trade-off that pits the paramount need for light weight against the uncompromising demand for ultimate durability. There is no single "best" material for every situation; rather, the optimal choice is dictated by your specific discipline, goals, and the intended application of the carabiner. Understanding the properties of each material is key to building a rack that is both efficient and fit-for-purpose.

This in-depth comparison will break down the characteristics of aluminum and steel to help you make an informed decision.

Aluminum Carabiners: The Climber's Standard

The vast majority of carabiners used in rock climbing, ice climbing, and alpinism are crafted from heat-treated aluminum alloy (typically 7000-series). This is for one overarching reason: the exceptional strength-to-weight ratio.

Advantages of Aluminum:

- Lightweight: This is the single biggest advantage. An aluminum carabiner typically weighs between 50-65 grams. When you need to carry dozens of them on a long trad route or multi-pitch climb, the weight savings compared to steel are substantial and directly translate to less fatigue and greater climbing performance.

- High Strength: Don't let the light weight fool you. A standard aluminum carabiner is rated between 22 kN and 28 kN (approximately 4,950 - 6,300 lbs of force), far exceeding the forces generated in even severe falls. When certified (UIAA/CE), they provide an immense and reliable safety margin.

- Cost-Effective: Aluminum carabiners are generally less expensive to manufacture than their steel counterparts, making them more accessible for building a complete rack.

Disadvantages of Aluminum:

- Lower Abrasion Resistance: Aluminum is a relatively soft metal. It can develop significant grooves from rope drag over time, and it is more easily damaged by being dropped on rock or grated against rough surfaces.

- Lower Overall Strength: While strong enough for climbing falls, aluminum has a lower ultimate tensile strength than steel. It is more susceptible to damage from sharp impacts or cross-loading.

Best For:

- Sport Climbing

- Traditional (Trad) Climbing

- Big Wall Climbing (where every ounce counts)

- Ice Climbing

- Alpinism and Mountaineering

- General all-around use

Steel Carabiners: The Industrial Specialist

Steel carabiners are the workhorses of the vertical world. They are made from carbon or stainless steel and are built for environments where abuse is a given.

Advantages of Steel:

- Superior Strength and Durability: This is the core strength of steel. Steel carabiners often have major axis strength ratings of 40 kN to 50 kN (9,000 - 11,250 lbs) or more. They are incredibly resistant to abrasion, making them ideal for situations where the carabiner will be constantly rubbed against rock, concrete, or metal.

- Excellent Abrasion Resistance: Steel is much harder than aluminum. It will show minimal wear from rope drag and is highly resistant to being cut. This makes them last significantly longer in high-friction environments.

- Better Heat Resistance: In situations involving friction from ropes (like a top-rope anchor under constant load), steel dissipates heat better and is less likely to be damaged by high temperatures.

Disadvantages of Steel:

- Heavy Weight: This is the critical trade-off. A steel carabiner can weigh 150-200 grams or more—three to four times the weight of a similar-sized aluminum carabiner. Carrying a rack of steel carabiners is impractical for most climbing disciplines.

- Cost: Steel carabiners are typically more expensive due to the material and manufacturing costs.

Best For:

- Permanent Anchors and Fixed Lines

- Via Ferrata Kits (where the carabiner is constantly abraded against a steel cable)

- Rescue and Industrial Rope Access

- Top-Rope Anchors at busy climbing areas (for their longevity)

- Abseil (Rappel) Points

Head-to-Head Comparison Table

| Feature | Aluminum Carabiner | Steel Carabiner |

|---|---|---|

| Weight | Light (50-65g) | Heavy (150-200g+) |

| Strength | High (22-28 kN) | Very High (40-50 kN+) |

| Durability | Good | Excellent |

| Abrasion Resistance | Fair | Superior |

| Cost | Generally Lower | Generally Higher |

| Primary Use | Personal Leading Rack | Fixed Gear, Rescue, Industry |

Conclusion: Matching the Material to the Mission

The choice between aluminum and steel is not about one being universally "better," but about selecting the right tool for the mission.

- For your personal climbing rack—the carabiners you clip to your harness for leads, protection, and belaying—aluminum is the undisputed champion. Its light weight is a performance-enhancing feature that allows you to climb harder, longer, and with greater comfort without sacrificing safety.

- For fixed, high-wear, or industrial applications where the carabiner will be left in place or subjected to constant abrasion, steel is the superior choice. Its brute-force durability and longevity in these punishing environments justify its weight penalty.

Ultimately, both materials are exceptionally safe when they bear the UIAA or CE certification mark. Your decision should be guided by a simple question: "Will this carabiner be moving with me, or will it be staying put?" The answer will clearly point you to the ideal material for your needs.

开启新对话