How to Fix a Stuck Telescoping Trekking Pole?

Few things are more frustrating on the trail than a trekking pole that refuses to collapse or extend. A stuck section can turn a simple adjustment into a major hassle, potentially compromising your hike. Before you resort to brute force—which can permanently damage your poles—understand that most jams are caused by dirt, moisture, or a misaligned mechanism. With patience and the right technique, you can almost always free the sections yourself.

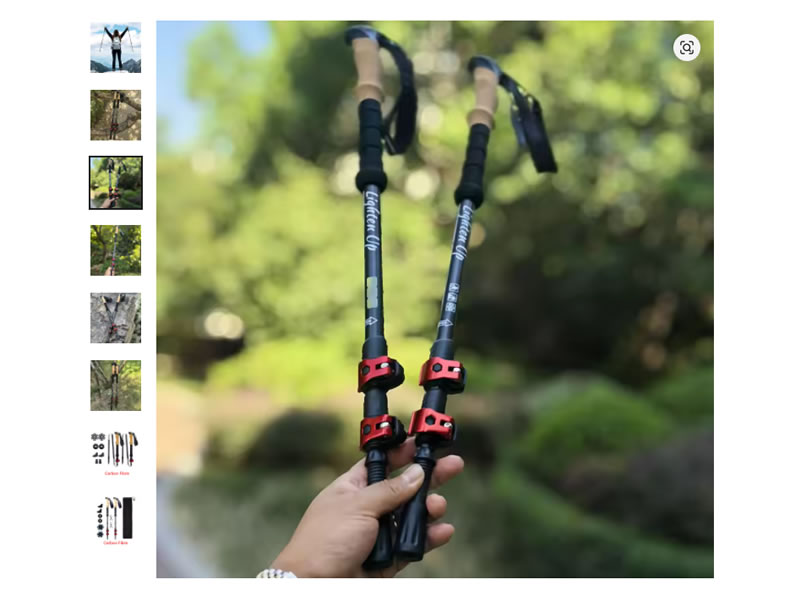

Buy Link: https://www.aliexpress.com/item/1005010266236215.html

Understanding Why Poles Get Stuck

To fix the problem, first identify the likely cause:

- Dirt & Grime Ingress: Fine sand, mud, or grit works its way into the shaft interface, acting as an abrasive glue.

- Moisture & Corrosion: Water, especially salty or mineral-rich, can cause aluminum components to oxidize and "cold-weld" together.

- Thermal Expansion/Contraction: Temperature swings (e.g., from a warm car to cold snow) can cause metal sections to expand or contract at different rates, creating a tight seal.

- Overtightened Locking Mechanism: A twist lock tightened excessively or a flick lock closed on an angled section can create a severe bind.

- Bent or Damaged Shaft: A subtle dent or bend can physically prevent the inner shaft from sliding.

Essential Tools & Preparations

Gather a few household items before you start:

- Protective Gloves: For grip and safety.

- Rubber Jar Opener or Latex Gloves: Increases grip strength tremendously.

- Hair Dryer or Heat Gun (on low): For applying controlled, gentle heat.

- Cool Water: To contrast with heat.

- Penetrating Lubricant (e.g., WD-40 Specialist Penetrant): For severe corrosion only.

- Soft Mallet or Block of Wood: For gentle tapping.

- Clean Rags and Isopropyl Alcohol: For final cleaning.

Golden Rule: Avoid Excessive Force. Never use pliers directly on the shaft (they will crush it) or apply extreme torque. Patience is key.

Step-by-Step Fix: By Lock Type

Part A: Fixing a Stuck Twist/Expander Lock Pole

Twist locks jam when grit infiltrates the expander plug inside the lower section.

- Release Tension: Attempt to unlock the mechanism by twisting the upper section counter-clockwise as far as it will go. Don't force it.

- Apply Gentle Heat: Use a hair dryer on a medium setting to warm the metal joint of the stuck sections for 60-90 seconds. Focus on the outer shaft. Heat causes metal to expand, potentially breaking the bond of corrosion or grime.

- Grip and Twist: Wearing rubber gloves or using a jar opener, grip both sections firmly. Try to twist the upper section counter-clockwise (to loosen) while simultaneously pulling the sections apart. A gentle, wiggling pull is more effective than a straight, hard pull.

- The Thermal Shock Method: If heat alone fails, rapidly cool the inner shaft. Pour cool water over the inner section (if accessible) or wrap it with a cold, wet rag while the outer is still warm. The differential contraction can break the seal.

- Penetrant as Last Resort: If you suspect corrosion, apply a small amount of penetrating lubricant to the seam and let it soak in for 10-15 minutes before repeating steps 2-3. Important: You must thoroughly clean the locking mechanism afterward with isopropyl alcohol to remove all oil before reuse.

Part B: Fixing a Stuck Flick/Lever Lock Pole

Lever locks usually stick because the locking collar is misaligned or the internal cam is jammed by grit.

- Ensure Full Release: Double-check that the lever is completely in the open/unlocked position.

- Tap to Vibrate: Hold the pole vertically and gently tap the stuck joint against a hard, flat surface like a wooden floor or step. The goal is to use vibration to dislodge packed grit and realign components. You can also use a soft mallet to tap around the circumference of the outer collar.

- Rotational Pull: While applying firm pulling force on the sections, also rotate them back and forth. This combines linear and rotational motion to overcome the bind.

- Inspect the Cam: If the lever feels loose but the section is stuck, the internal cam might be broken or jammed. You may need to disassemble the lever mechanism (if possible) or seek professional repair.

Prevention: How to Keep Your Poles from Sticking Again

- Clean After Every Muddy/Wet Hike: Wipe down and fully extend poles to dry internally.

- Pre-Clean Before Adjusting: Briefly wipe lower sections free of grit before collapsing them into cleaner upper sections.

- Avoid Overtightening: For twist locks, snug is sufficient. For flick locks, ensure sections are straight before clamping down.

- Store Correctly: Keep poles clean, dry, and slightly extended or fully collapsed—not partially extended under tension.

- Regular Maintenance: Periodically clean locking mechanisms with a dry brush and isopropyl alcohol.

When to Seek Professional Help

If all methods fail, or if you see visible dents, cracks, or broken plastic components, contact the manufacturer's customer service or a gear repair shop. Forcing a truly damaged pole can lead to sudden failure on the trail.

A stuck trekking pole is a common nuisance, but it's rarely a death sentence for your gear. By understanding the cause and applying a methodical, gentle approach, you can free the sections, perform a thorough cleaning, and return to the trail with confidence. Regular care is the simplest guarantee that your poles will adjust smoothly for years to come.