How to test a climbing swivel ring for wear and tear?

A climbing swivel ring’s reliability hinges on its ability to rotate smoothly under load. Over time, dirt, corrosion, and stress can compromise its integrity, turning a safety device into a liability. Regular testing for wear and tear is non-negotiable—whether you’re a weekend climber or a professional rigger. This guide walks you through actionable methods to assess your swivel ring’s condition, spot hidden flaws, and decide when to retire it.

Why Testing Matters

Swivel rings endure:

- Abrasion: Rubbing against ropes, rock, or metal.

- Corrosion: Exposure to sweat, saltwater, or chemicals.

- Cyclic Loading: Repeated stress from twists and pulls.Undetected wear can lead to sudden failures, such as seized rotation or catastrophic cracks.

Tools You’ll Need

- Magnifying glass or smartphone macro lens.

- Caliper (optional, for measuring deformation).

- Load-rated carabiner and anchor (for stress testing).

- Dry lubricant (e.g., silicone spray).

- Cleaning supplies (brush, mild soap, water).

Step 1: Pre-Test Cleaning

Dirt can mask damage. Clean the swivel ring thoroughly:

- Rinse with water to remove loose debris.

- Scrub with a soft brush and mild soap, focusing on bearings and crevices.

- Dry completely to avoid moisture interference.

Step 2: Visual Inspection

A. Surface Examination

- Cracks: Use a magnifier to check the body, eyelets, and weld points. Even hairline cracks are red flags.

- Corrosion: Look for rust, pitting, or discoloration, especially in stainless steel or aluminum joints.

- Deformation: Check if the ring is oval-shaped (should be perfectly round).

B. Bearing Inspection

- Remove dirt from bearings (if open design).

- Check for chipped ceramic balls or rusted steel bearings.

Step 3: Rotation Test

- Hold the swivel ring firmly and spin it manually.Pass: Smooth, silent rotation.Fail: Grinding, stiffness, or uneven movement.

- If stiffness occurs:Apply dry lubricant and retest.Persistent issues indicate bearing damage or internal debris.

Step 4: Load Test

Never skip this step—some flaws only appear under tension.

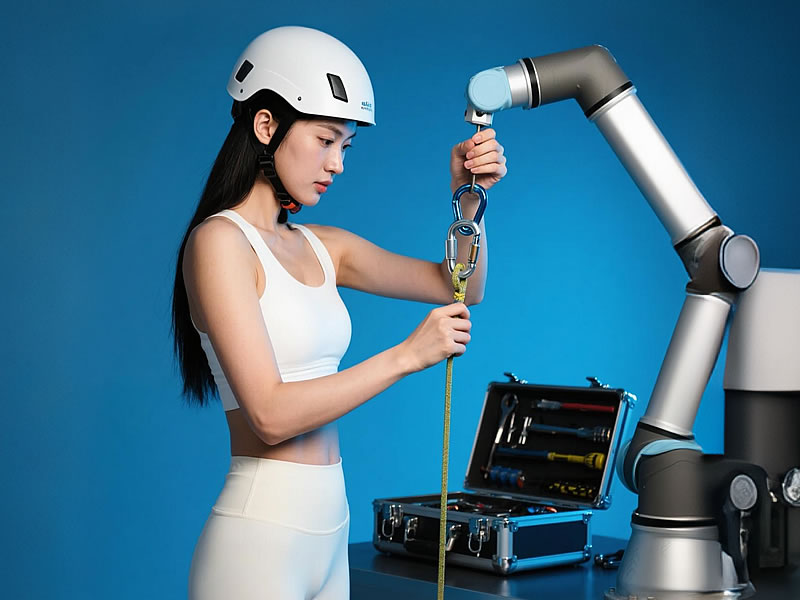

- Setup: Attach the swivel to a secure anchor via a load-rated carabiner.

- Apply Load: Gradually add weight (e.g., 10–20% of its max rating) using a sandbag or controlled rigging system.

- Observe:Rotation Under Load: The swivel should pivot freely without binding.Deformation: Stop immediately if the ring bends or creaks.Post-Test Check: Re-inspect for new cracks or elongation.

Step 5: Measure Wear

Use a caliper to detect subtle changes:

- Diameter: Compare the swivel’s eyelets to manufacturer specs.

- Bearing Play: Excessive wobble in bearings suggests wear.

- Weight Loss: Significant material loss (common in aluminum) weakens the structure.

Common Signs of Wear

- Gritty Rotation: Dirt in bearings or lack of lubrication.

- Discoloration: Heat damage from friction (bluish tint on steel).

- Thread Damage: Worn or stripped threads on screwgate models.

- Creaking Sounds: Internal corrosion or fatigue.

When to Retire a Swivel Ring

Replace the swivel immediately if you find:

- Cracks or Deep Pitting: Compromises structural integrity.

- Permanent Deformation: Bent eyelets or oval shape.

- Irreversible Bearing Damage: Grinding persists after cleaning/lubrication.

- Exceeded Lifespan: Most manufacturers recommend replacement after 3–5 years of regular use.

Testing Frequency

- Recreational Climbers: Test every 6 months or after 50 uses.

- Professionals: Test monthly or after exposure to harsh conditions (e.g., saltwater, mud).

- Post-Incident: Always test after a fall, shock load, or visible impact.

Case Study: The Hidden Flaw

A climber’s swivel ring passed visual checks but seized mid-rappel due to internal corrosion in the bearings. Post-accident analysis revealed saltwater residue from coastal climbs had corroded the steel bearings unnoticed. This underscores the need for:

- Disassembly Checks (if possible).

- Routine Lubrication in corrosive environments.

Pro Tips for Accurate Testing

- Compare New vs. Old: Keep a new swivel ring as a reference for smoothness and shape.

- Document Findings: Log inspection dates, wear patterns, and retirement dates.

- Use Certified Gear: UIAA/CE-certified swivels undergo rigorous factory testing.

Conclusion: Safety Through Diligence

Testing a climbing swivel ring isn’t just a checklist—it’s a lifesaving habit. By combining visual scrutiny, mechanical checks, and load testing, you catch flaws before they escalate. Remember: No piece of gear is indestructible. When in doubt, retire the swivel and replace it. Your vigilance ensures that every rotation is a step toward safety, not a spin of chance.

Final Note: Pair testing with regular maintenance. A clean, lubricated swivel ring is easier to assess and lasts longer.